Pharmaceutical manufacturing comprises physical processes such as blending, granulation, coating, and drying.

Dryer line are used to remove liquids or moisture from bulk solids, powders, or other liquids by evaporation or sublimation.

Drying is the process of removing the presence of solvents (i.e. water or other liquids) in a formulation with the presence of heat.

This process is widely used in the pharmaceutical field, from research and development phase until large-scale manufacture

GRANULATOR

GM Series high shear mixer granulator is used in pharmaceutical solid dosage area for mixing and granulation application.

It’s the major processing equipment in solid dosage production line.

The equipment is PLC automation controlled and well satisfies the current GMP and Pharmacy Code regulation

FLUID BED DRYER

FBG Series fluid bed dryer & granulator is used in pharmaceutical solid dosage area for mixing, granulation and drying application, or drying of the wet granules processed from high shear mixer granulator.

It’s the major processing equipment in solid dosage production line.

The equipment is PLC automation controlled and well satisfies the current GMP and Pharmacy Code regulation.

MIXING MACHINES

The HF series square-cone mixing machine is a novel material mixer extensively used in the pharmaceutical, chemical, metallurgical, food, light and feed industries. This machine can mixer powder or granules very evenly so that the mixed materials can reach the best effect.

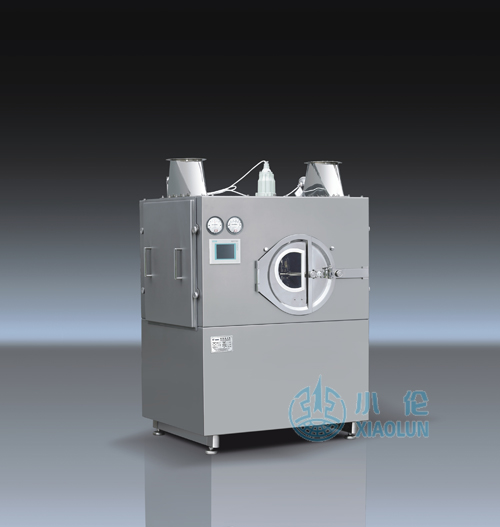

The Coating Machine is mainly used in pharmaceutical and food industries. It is a high-efficiency, energy saving, safe, clean and mechatronics equipment for coating tablets, pills and candies with organic film, water soluble film, slow and controlled release film and sugar film etc., which conforms to the requirement of GMP.